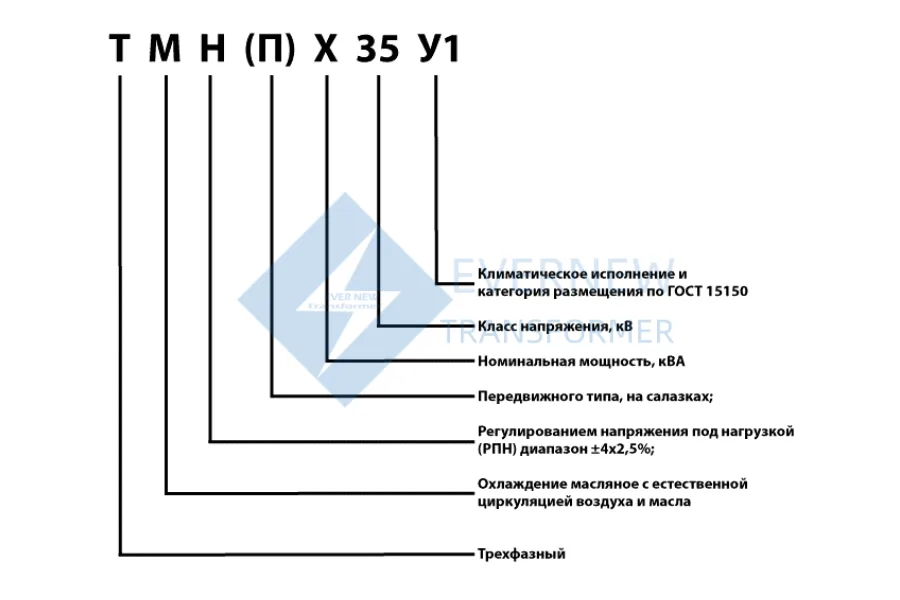

TMH transformers are high-efficiency three-phase oil transformers with two windings that provide on-load voltage regulation (OLC) with an accuracy of ±4x2.5%. They are designed for applications with maximum input voltages up to 110 kV and capacities from 1000 kVA to 6300 kVA. These transformers are ideal for industrial and distribution networks, providing efficient power transmission with minimal losses.

TMN transformers have natural oil cooling, which ensures durability and reliable operation under various climatic conditions. They are equipped with modern voltage regulators and can be used in regions with temperatures from -50°C to +40°C. Such devices ensure stable operation of power grids and guarantee high efficiency throughout their entire service life.

The TMN transformer operates on the basis of the principle of electromagnetic induction. Voltage is transferred between the two windings by means of a magnetic field, which allows to change its characteristics depending on the required network parameters. This process makes it possible to effectively increase or decrease the voltage, which is important for ensuring stable power supply in distribution and industrial networks.

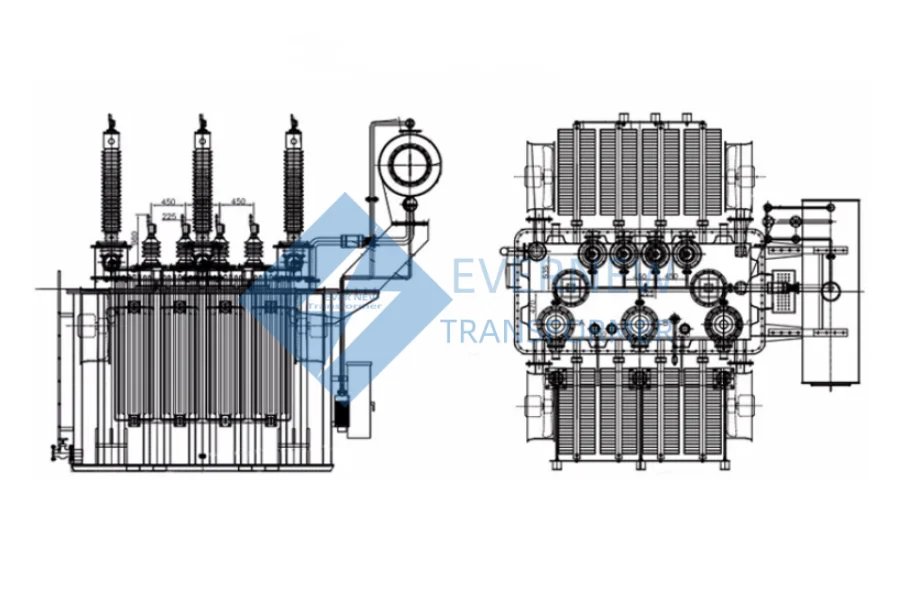

The main components of the TMH transformer:

- Case: is made of welded metal construction, which ensures rigidity and tightness of the unit. Strong connections prevent oil leakage and increase the service life of the unit.

- Magnetic system: is made of cold-rolled electrical steel, which minimizes energy losses and contributes to high operating efficiency.

- Windings: The high-voltage and low-voltage windings are in the form of block coils made of copper or aluminum. They provide excellent conductivity and durability.

- Oil tank: hermetically sealed design that protects the transformer oil from external contaminants and increases the reliability of the device.

- Terminals: are used to connect the transformer to the electrical network, providing reliable current input and output.

- Instrumentation: to monitor the transformer status, which allows timely detection of possible malfunctions and prevention of breakdowns.

Quality Management - Evernew Transformer

Evernew Transformer adheres to strict quality standards and high quality manufacturing. All products undergo a two-stage quality assurance process to ensure the efficiency and durability of TMH transformers.

Quality control of materials and components: All materials such as copper wires, insulation materials and transformer oil are thoroughly tested to meet international standards.

Acceptance testing and testing: Each transformer is comprehensively tested to ensure that its performance meets design requirements and international standards. Key test parameters include:

- Measuring winding resistance to control energy losses.

- Transformer ratio measurement to check the accuracy of voltage conversion.

- Checking the tightness and stability of the structure.

Advantages of TMH transformers from Evernew Transformer:

- StepLap Magnetic System: with an innovative design that reduces idling losses, improving device efficiency.

- Minimizing electrical losses: TMH transformers significantly reduce energy losses due to the use of quality materials and well thought-out design.

- Sealed oil tank: provides protection against external contaminants, extending the life of the transformer.

- Safety and Reliability: transformers are equipped with safety valves that protect against overloads and overpressure.

- Resilience: TMN transformer design is vibration and mechanical resistant, making it ideal for use in harsh environments.

- Flexibility in customization: offers customized solutions for each customer, including voltage regulation and the ability to operate in specific climatic conditions.

- Wide range of operating conditions: TMN transformers can operate in a wide variety of climatic conditions, from moderately cold to arctic climates, ensuring reliable operation at extreme temperatures.

About the company

Evernew Transformer is a leading Chinese transformer manufacturer that has been providing high quality solutions to the power industry for over 30 years. The company covers more than 500 hectares of land and produces tens of thousands of transformers annually, including TMH series products. With state-of-the-art technology, highly skilled engineers and extensive production facilities, we provide reliable equipment for various industrial and distribution networks around the world.

One of the flagship areas of the company is the production of TMN transformers. These devices are designed to work effectively in a wide variety of climatic and operating conditions, ensuring stable power supply in any conditions. Our TMH transformers meet international quality and safety standards including GOST, CE and UL. We also provide flexible solutions for customization and adaptation of products to meet our customers' requirements.

Evernew Transformer's manufacturing facilities are equipped with advanced metalworking and assembly lines, enabling us to provide high quality products and meet tight delivery deadlines. Our TMH transformers are available in various capacities and voltages and are ideal for use in industrial, distribution and power networks.

Manufacturer's warranty

Evernew Transformer provides warranties on all products, including TMH transformers. During the warranty period, the company will repair all defects caused by manufacturing errors and replace damaged components. In order to receive warranty service, customers must comply with the transportation, storage, installation and operating instructions specified in the technical documentation. Failure to comply with these conditions may invalidate the customer's warranty.

Contacts

For more information about TMH transformers or to order customized solutions, please contact us. We are ready to offer you professional advice and technical support to select the optimal equipment for your project.

We look forward to working with you and are confident that our experience and products will help your project succeed!