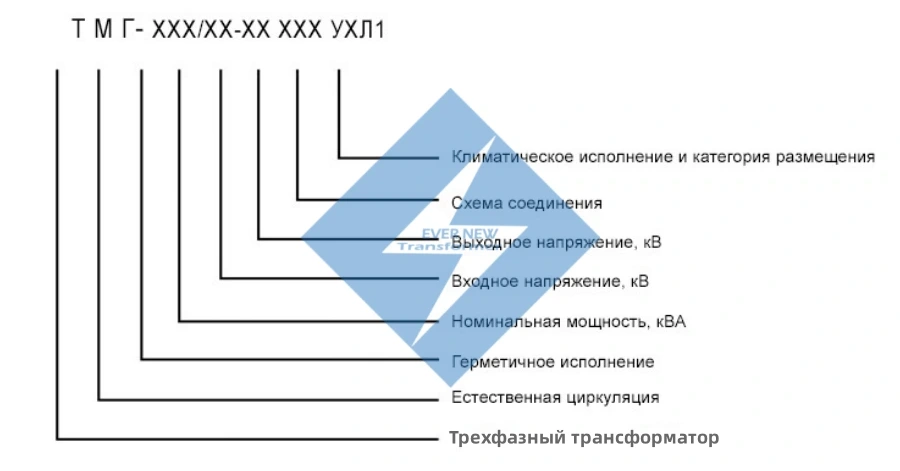

Power transformers TMG

TMG transformer is a three-phase oil transformer with natural cooling, designed for operation in electrical networks with a frequency of 50 Hz. These transformers are effective in electric energy conversion (voltage reduction or increase) and provide stable power supply for consumers in various industries.

Operating conditions of TMG Transformer

The TMG transformer has a wide operating temperature range, making it versatile for various climatic conditions. The optimum ambient temperature for its operation is from -45°C to +40°C, while for operation in colder regions it is possible to extend the range to -60°C. These transformers are ideally suited for moderately cold climates and provide reliable operation in such conditions.

- Installation height: up to 1000 meters above sea level.

- Environment: it is recommended to avoid operation in areas with conductive dust, corrosive or explosive gases, or in areas with high concentrations of steam or chemically active substances.

- Vibration and shock: TMG transformers are not designed for operation under severe vibration or shock loads.

Design and features of TMG Transformer

The TMG transformer consists of high quality components ensuring its durability and high efficiency:

- Case: welded metal construction with elliptical or rectangular body. Strong connections and tightness are achieved by using high quality materials such as oil resistant rubber products.

- Magnetic system: made of cold-rolled electrical steel, which contributes to minimal transformer losses and increased reliability.

- High and low voltage windings: made as block coils of copper or aluminum for excellent conductivity and durability.

- Cooling: naturally cooled, which helps to reduce operating costs and extends the service life of the unit.

Standards and certification

The TMG transformer complies with international quality standards including GOST, CE and UL. It meets the climatic conditions of GOST 15150, categories U1 and UHL1, making it an ideal choice for use in a wide range of temperatures and operating conditions.

Main parameters of TMG transformer:

- Power: 16 kVA to 2500 kVA

- Voltage: high - 6 kV, 10 kV, 20 kV, 35 kV; low - 0.4 kV, 0.69 kV, 3.15 kV, 6.3 kV, 10.5 kV.

- Defense: protection class IP00.

Long service life

TMG transformer is designed for a service life of up to 30 years under the operating conditions, which makes it a profitable investment for enterprises and power supply companies.

Quality Management - Evernew Transformer

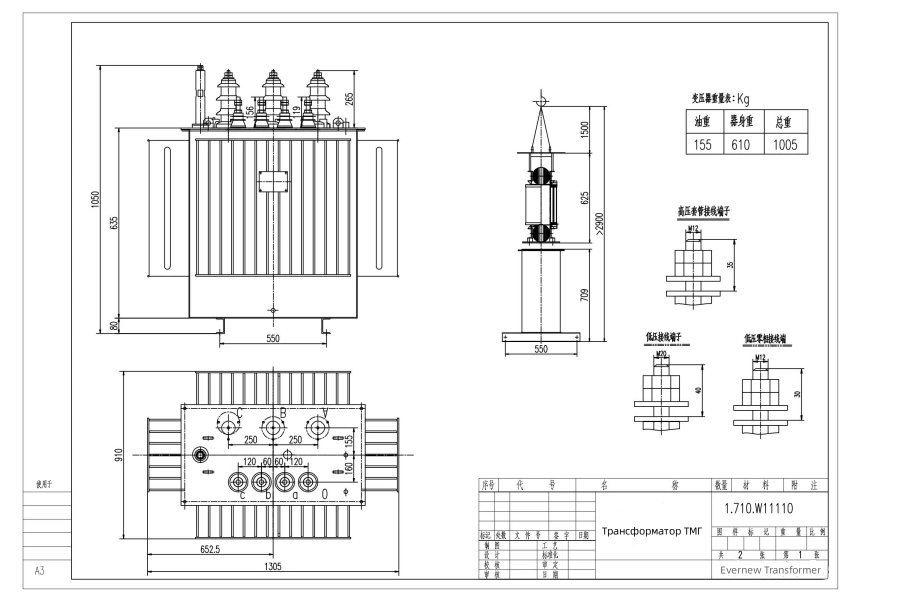

Transformer TMG standard dimensions

| Name | Rxx,W | Rkz, W | Current xx, % | Ukz% | Frequency, Hz | Gross weight, kg | Length, mm | Width,mm | Height, mm |

|---|---|---|---|---|---|---|---|---|---|

| TMG-16 | 90 | 600 | 2,6 | 4,5 | 50 | 317 | 795 | 420 | 1075 |

| TMG-25 | 90 | 600 | 2,6 | 4,5 | 50 | 317 | 795 | 420 | 1075 |

| TMG-40 | 125 | 895 | 2,6 | 4,5 | 50 | 310 | 800 | 480 | 1090 |

| TMG-63 | 170 | 1420 | 2,5 | 4,5 | 50 | 380 | 880 | 550 | 1250 |

| TMG-100 | 200 | 1785 | 1,4 | 4,5 | 50 | 490 | 890 | 720 | 1250 |

| TMG-160 | 357 | 2535 | 1,4 | 4,5 | 50 | 680 | 940 | 730 | 1320 |

| TMG-250 | 540 | 3290 | 1,3 | 4,5 | 50 | 1285 | 1010 | 1010 | 1450 |

| TMG-400 | 705 | 4755 | 0,8 | 4,5 | 50 | 1500 | 1295 | 1010 | 1610 |

| TMG-630 | 820 | 6580 | 0,6 | 5 | 50 | 2250 | 1390 | 1160 | 1650 |

| TMG-1000 | 1190 | 9650 | 0,5 | 5,5 | 50 | 3300 | 1750 | 1220 | 1850 |

| TMG-1250 | 1400 | 11350 | 0,5 | 6 | 50 | 3600 | 1910 | 1260 | 1860 |

| TMG-1600 | 1750 | 13900 | 0,5 | 6 | 50 | 3800 | 2330 | 1360 | 2140 |

| TMG-2500 | 2450 | 19800 | 0,5 | 6,5 | 50 | 4300 | 2400 | 1440 | 2280 |