What is a dry-type transformer

A dry-type transformer is an electrical converter that uses air cooling instead of liquid cooling agents. It does not require oil leakage control and regular oil changes, which significantly reduces operating costs. This type of transformer complies with GOST R 54827-2011 standard, providing a high level of safety and ease of operation. Due to their environmental friendliness, dry-type transformers are widely used in areas with high safety requirements, such as public buildings, oil and gas enterprises, metallurgy, nuclear power plants, as well as in the paper and pulp industry. They can be manufactured using vacuum or non-vacuum technology to provide highly efficient and stable power conversion in a variety of industrial environments.

Types of dry-type transformers:

- TC - Free-cooled transformers used in moderate environments.

- TSZ - Forced air-cooled transformers suitable for high loads.

- TSZL - Models with extra protection against external influences, ideal for demanding environments.

- TSL - Low noise transformers used in residential and office buildings.

- TSN - Transformers with increased protection for severe operating conditions such as high humidity or aggressive media.

Advantages of dry-type transformers compared to oil transformers

Starts and certification

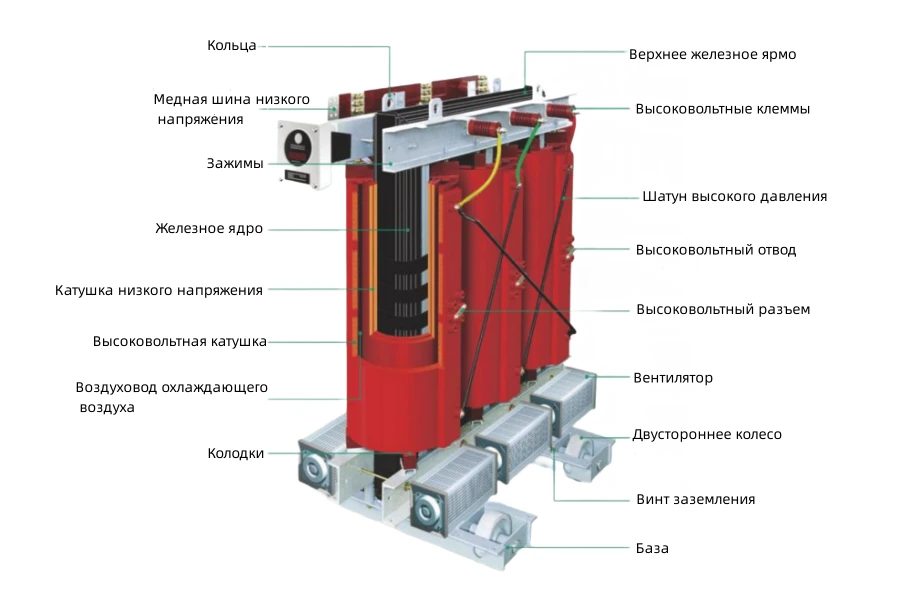

Main components of dry-type transformers and their materials

Housing (Material: steel, aluminum)

Used to support the entire transformer structure, providing strength and stability. Steel and aluminum alloys are lightweight and strong, ensuring a robust and sturdy structure.Winding terminals (Material: copper, aluminum)

Designed for current input and output, ensuring stable connection of the transformer to the grid. Copper and aluminum have good conductivity, which ensures efficient power transmission.Transformer core (Material: silicon steel)

Made of high quality silicon steel, it is the main element for electromagnetic energy transmission. The material has low losses and high magnetic permeability.Cooling system (Material: aluminum alloys, plastic)

Cooling by natural airflow or forced ventilation ensures stable operation of the transformer under high loads. Aluminum alloys and plastic contribute to the cooling efficiency.Control and measuring devices (Material: metal, plastic)

They are used to continuously monitor the transformer status and ensure its safe operation. The housing of the devices is usually made of heat-resistant plastic and metal, which protects the internal electronic components.Insulation materials (Material: epoxy resin, paper, ceramic)

Designed to electrically insulate and provide effective insulation. Epoxy resin, insulating paper and ceramics provide high stability and long life.Shell (Material: steel, aluminum)

The shell protects the transformer from external shock and contamination. Steel and aluminum have good corrosion resistance and strength, making them ideal for use in a variety of environments.Overload protectors (Material: metal, plastic)

Prevent damage to the transformer in case of overload. Protective devices are usually made of metal and heat-resistant plastic to effectively protect the transformer under abnormal loads.Fans (Material: aluminum, steel)

Promote air circulation and reduce transformer temperature, maintaining stable operation. Aluminum and steel fans are resistant to high temperatures and effectively cool the equipment.Cushioning devices (Material: rubber, steel)

Reduce vibrations during transportation and operation by protecting the transformer from mechanical shocks. Rubber provides cushioning and steel provides the necessary strength and support.

Care and operation of dry-type transformers

Dry-type transformers require a specific maintenance approach to ensure their long-term and safe operation. The maintenance plan and frequency of maintenance should be in accordance with the manufacturer's recommendations, national standards and industry regulations. In general, maintenance of dry-type transformers includes the following activities:

- Cleaning the transformer surface of dust to improve heat dissipation.

- Check the effectiveness of natural or forced ventilation.

- Checking the tightening of bolted connections.

- Check the condition of the paintwork for signs of overheating, abnormal color changes, or signs of electrical damage.

- Inspection of the condition of thermal insulation devices and protective elements.

Electrical equipment of dry-type transformers is inspected according to the established schedule. Maintenance activities and inspections are recorded in the operators' working documents and must be carried out in accordance with the requirements of the operating regulations. Visual inspections and thermal imaging measurements shall be carried out with the transformer running; in all other cases the power supply must be disconnected.

The dry-type transformer with standardized dimensions offers efficient solutions for industrial and distribution networks. These transformers are characterized by high reliability and compactness, allowing them to be used in confined spaces under various climatic conditions. The dimensions can be varied according to capacity and technical requirements, with the possibility of customization to meet specific customer needs.

| Rated power kVA | Overall dimensions (mm, not more) | Weight | ||

|---|---|---|---|---|

| L (length) | B (width) | H 1 (full height) | ||

| 25 | 725 | 555 | 870 | 365 |

| 40 | 820 | 85 | 920 | 425 |

| 63 | 900 | 650 | 985 | 655 |

| 100 | 900 | 650 | 985 | 655 |

| 160 | 980 | 650 | 1175 | 1010 |

| 250 | 1035 | 700 | 1215 | 1270 |

| 400 | 1120 | 795 | 1280 | 1550 |

| 630 | 2100 | 1150 | 1655 | 2410 |

| 1000 | 2000 | 1200 | 1900 | 2870 |

| 1600 | 2100 | 1150 | 1655 | 2410 |

| 1250 | 2010 | 1300 | 2300 | 4100 |

| 2500 | 2850 | 1455 | 2735 | 4100 |