What is a power transformer?

A power transformer is an electromechanical device that finds a wide range of applications, including in the household, electrical power, radio electronics and radio engineering industries. Its main function is to transfer electricity between different circuits by magnetic induction, changing the voltage level as required. Power transformers meet various power transmission requirements by converting alternating current of one voltage into alternating current of another voltage, while maintaining a stable current frequency.

Transformers are the most common electrical devices in industry and everyday life. Their main function is to reduce or increase the voltage between the power source and the consumer depending on the load requirements. Transformers are also widely used in power circuits to convert alternating current to direct current. By changing the voltage, power transformers can efficiently transmit electricity and ensure stable operation of the power supply system.

What elements does a transformer power supply include?

The transformer power supply design includes one or more individual windings that are in the same magnetic flux and wound on a magnet core made of ferromagnetic material.

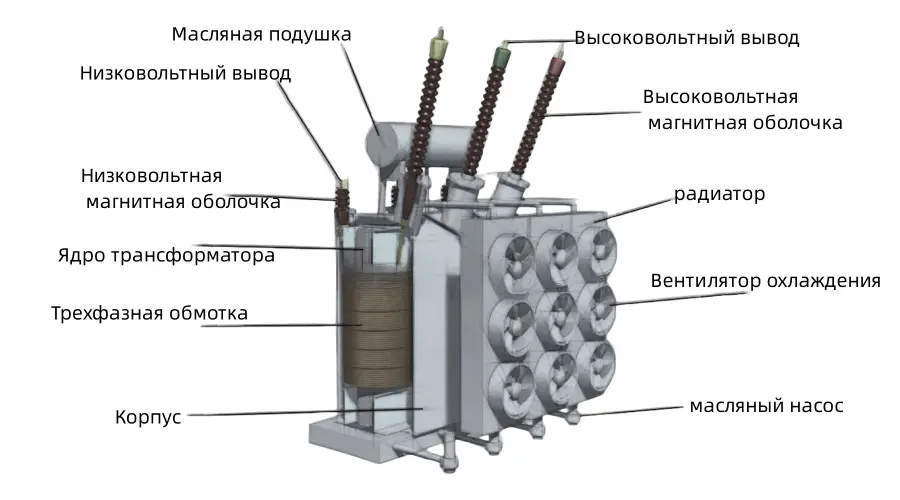

The main components of a power transformer:

- Body (frame);

- Windings;

- Magnetic circuit;

- Leads and connections;

- Insulation;

- Voltage regulation;

- Cooling system;

- Additional accessories.

Magnetoconductor serves to return the magnetic flux and has a reduced magnetic flux resistance. The windings consist of two types of aluminum conductors. The primary winding receives current from an external source and the secondary winding provides voltage reduction. Each winding consists of three-phase elements that are connected in a star, delta, sawtooth, or Z-shaped circuit.

Conclusions are used to supply current to the transformer. Depending on the transformer type, the terminals can be equipped with oil barriers, polymer, SF6 or paper-oil insulation.

Voltage regulation allows to change the transformation ratio by changing the number of turns in the windings. Additional devices include gas relays, temperature indicators, dryers, continuous oil recovery system and oil level indicators.

Each power transformer consists of a magnetic core with several windings made of ferromagnetic materials. These are usually special transformer sheets with soft magnetic properties, which are stacked so that the cross-section of the core under the windings is close to a circle. To increase the efficiency of the device and reduce losses, the connections between the sheets are closed.

Transformer windings are usually made of copper with rectangular or circular cross-section, and each winding is insulated both from the magnetic core and from neighboring windings. Technical gaps are left between the winding layers for the circulation of the cooling medium.

Every transformer has at least two windings: a primary winding (receiving current) and a secondary winding (changing voltage and transmitting current).

Principle of operation of an electrical transformer

The principle of operation of a power transformer is based on the phenomenon of electromagnetic induction. When alternating current is applied to the primary winding, it creates an alternating magnetic flux in the magnetic core. This magnetic flux is closed on the magnetic core, forming a coupling between the windings, which causes an induced electromotive force (EMF). Voltage and current are generated in the secondary winding to which the load is connected.

A certain ratio of turns between the primary and secondary windings is used to obtain the required secondary voltage. A power transformer has the property of reversibility, which allows it to work for both step-up and step-down voltage. For example, in a step-up transformer, the voltage on the primary winding will be lower than on the secondary winding.

Types of power transformers

Power transformers can be classified according to various characteristics including purpose, power, magnetic circuit type, number of phases and other parameters.

By purpose power transformers can be divided into:

- Step-down transformers - are used to step down from higher to lower voltages in distribution networks.

- Step-up transformers - are used for voltage boosting to transmit electricity over long distances.

By type of magnetic circuit transformers are divided into:

- Armored transformers - have a magnetic conductor consisting of "E" type plates, which are insulated from each other with varnish. These devices have non-uniform magnetic flux and are easy to mount. They are usually used in large household appliances.

- Pillar transformers - have a different winding installation method and magnetic circuit design. The magnetic circuit consists of strips of electrical steel. These devices differ in that the windings are outside, unlike armored devices.

- Transformers with ring magnet core - are the most efficient, but their production is complex and labor intensive. The magnetic core is a closed ring structure and the windings are wound directly onto the magnet core. The cost of such transformers is usually higher due to the labor-intensive production.

By number of phases there are transformers:

- Single-phase - are used for small consumers or in distribution networks.

- Three-phase - are more common, used in power grids, especially in large converter stations and industrial plants.

By type of cooling:

- Dry-type transformers - cooling is air-cooled, making them ideal for installation in areas with high safety requirements.

- Oil transformers - are used for larger capacities where cooling is achieved with oil, which insulates the windings and helps dissipate heat.

On installation:

- For indoor installation - these transformers are typically used for power distribution in enclosed areas such as transformer stations.

- For outdoor installation - are designed for use in open environments, e.g. in distribution networks or large plants.

By capacity power transformers can be classified as follows:

- Up to 100 kVA, up to 35 kV

- 100 - 1000 kVA, up to 35 kV

- 1000 - 6300 kVA, up to 35 kV

- 6300 kVA and above, up to 35 kV

- Up to 32,000 kVA, 35 - 110 kV

- 32,000 - 80,000 kVA, up to 330 kV

- 80,000 - 200,000 kVA, up to 330 kV

- Over 200,000 kVA, over 330 kV

Other important characteristics:

- Availability of output voltage regulator - Some models have the ability to adjust the output voltage to maintain stable parameters.

- Climatic version - can be devices for operation in both extreme and normal climatic conditions.

Power transformers play a key role in the transmission and distribution of electricity, and the selection of the right type depends on many factors such as capacity, operating conditions and safety requirements.

Power transformer parameters

When choosing a power transformer, the important characteristics are its technical parameters, which determine the efficiency 和 safety of its operation。 Here are the main parameters you should pay attention to:

Rated power:Defines the maximum power that the transformer can transmit without overheating. For two-winding transformers it is the power of each winding, for three-winding transformers it is the power of the larger winding.

Rated voltage:The voltage at which the transformer operates under normal no-load conditions. Each winding has its own rated voltage.

Rated current:The maximum current that the transformer can transmit for a long time without overheating.

Short-circuited voltage:The voltage across the windings when the secondary side is short-circuited, which characterizes the winding resistance.

Short-circuited losses:Short circuit energy losses determining transformer efficiency.

No-load loss:The energy losses in a transformer when it is operating without load are mainly due to magnetic saturation of the core.

Idle current:The current flowing when the transformer is idling, which affects energy losses.

Transformation ratio:The ratio of the voltages on the primary and secondary windings that determines the degree of voltage change.

Power factor (COSφ)::The ratio of active to total power, reflecting the efficiency of the transformer.

Cooling system:A cooling system that prevents the transformer from overheating. It can be air or liquid, depending on the power of the unit.

How to choose a power transformer?

The selection of a power transformer for a plant depends on several key factors, including the power required and the level of reliability of the power supply. It is important to take into account that, in order to ensure uninterrupted power supply, it is sometimes necessary to install several transformers so that if one of them fails, the others can take over its functions. This also involves taking into account possible overloads that may occur during operation.

Key parameters for transformer selection:

Power

To select a transformer, it is important to accurately determine its required capacity, which must ensure reliable operation of the equipment. In the event of failure of one device, the others must be able to compensate for its operation.

Reliability and protection

When selecting a transformer, the availability of protection systems against various faults should be considered:

- Protection from internal damage: The transformer must be equipped with devices for monitoring gas, temperature, pressure and oil level to prevent malfunctions.

- Overload protection: Current transformers are recommended for installation in each phase to provide overload protection. In addition, differential protection is used to prevent damage.

Cooling and operating conditions

The transformer cooling system must be adapted to the operating conditions. Depending on the capacity of the device, different cooling systems can be used: air, oil or using additional cooling equipment.

Evernew Transformer Series Recommended Transformer Series

Company Evernew Transformer offers a wide range of transformers for different needs, including models with different power and voltage levels.

TMG series

For networks with voltages up to 10 kV it is recommended to use TMG series transformers. They are designed for outdoor installation and can operate under temperature fluctuations, as well as at heights up to 1000 m. The power of transformers of this series varies from 25 to 1000 kVA. The units are fully hermetically sealed and equipped with all necessary sensors for monitoring pressure, temperature and oil level. Protection against overpressure is provided by a special compensation system.

TMGSU series

This series are three-phase transformers that provide stable operation for both voltage variation and phase symmetry. TMGSU transformers are equipped with additional valves for protection against pressure drops, which eliminates equipment damage in case of overload or operational errors.

Transformers for high voltages (up to 500 kV)

For higher voltages, from 35 kV to 500 kV, Evernew Transformer offers transformers with capacities from 1 MVA to 200 MVA. These units are ideal for industrial applications and operate in a variety of climatic conditions to ensure high efficiency and durability. The range incorporates all the necessary protection and monitoring systems to ensure safe operation throughout its lifetime.

Types of transformers by purpose and function:

Oil transformers (oil cooled)

Suitable for installations where a high degree of protection and durability is required. The oil in the transformer provides not only cooling but also insulation.

Dry-type transformers

These units utilize air cooling, making them more environmentally friendly and safer for residential and commercial applications. They are ideal for installation in areas with high fire safety requirements.

Substation transformers

Designed for power distribution in electrical substations. These devices can be either single-phase or three-phase and are typically used for large-scale power systems.

Transformers for distribution networks

These transformers can be installed anywhere where voltage changes are needed to power industrial facilities or residential neighborhoods.

Transformers for special applications

Include transformers designed for specific applications, such as solar or wind power systems, where a high degree of stability and efficiency is important.

Recommendations for selection:

Consider the climatic conditions

Depending on the region of operation, the choice of cooling and protection will depend on climatic features (e.g. temperature, humidity, precipitation levels).

Power selection

It is necessary to correctly calculate the transformer capacity to match the needs of your equipment and to ensure uninterrupted operation under possible overloads.

Pay attention to warranty and service

Make sure that the transformer has a warranty and that there is a service and parts replacement option in case of failure.

Company Evernew Transformer offers high quality and reliable transformers that will ensure a safe and stable power supply for your company.